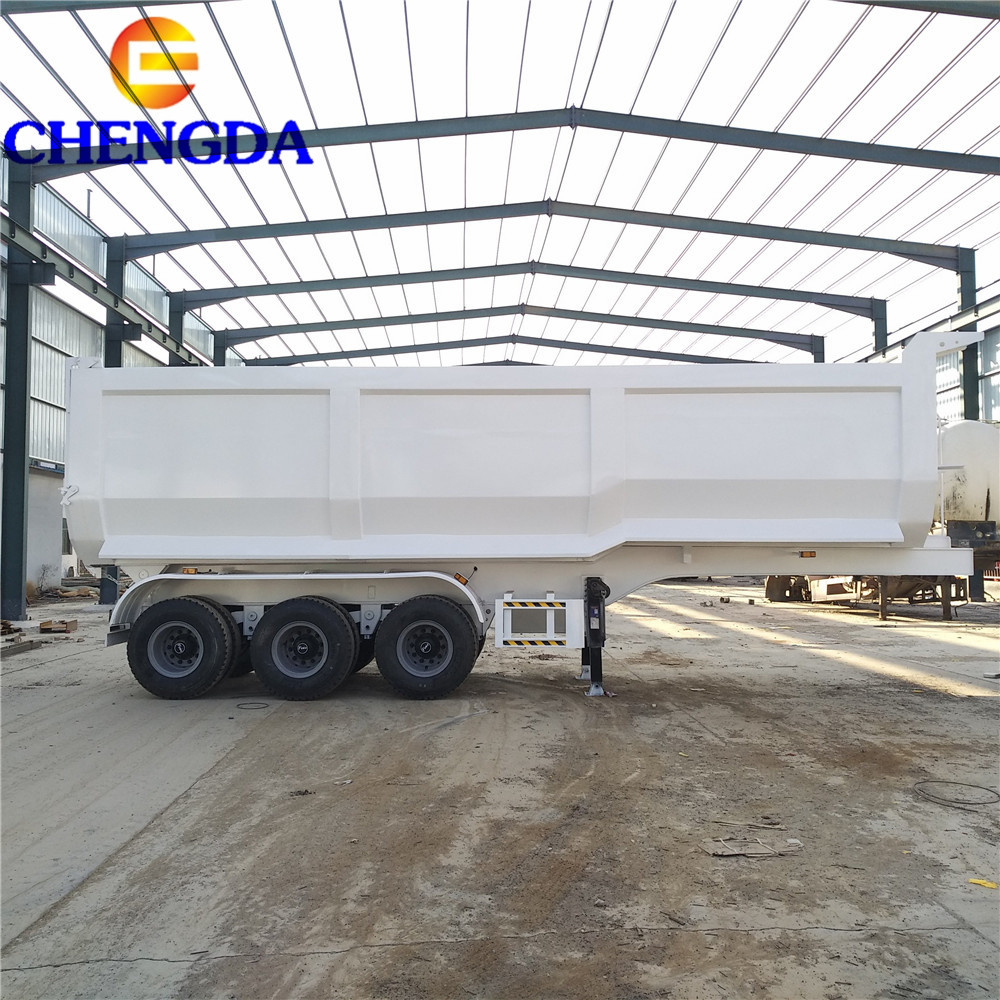

3 Axle U Shape Rear Tipper Semi Trailer

3 Axle U Shape Rear Tipper Semi Trailer is a new type of semi-trailer tipper. It has the characteristics of low center of gravity and easy to overturn when lifting. Both the frame and the frame have obtained national patents, and the frame is made of manganese beam plate, which greatly increases the bearing strength. The center of gravity is lowered, the 3 Axle U Shape Rear Tipper Semi Trailer is not easy to roll over during transportation, and the damage to the tires, leaf springs and frame is greatly reduced. The carriage adopts a narrow front and rear wide pattern. According to the triangle principle, when the carriage is lifted, its center of gravity is relatively concentrated.

For the 3 Axle U Shape Rear Tipper Semi Trailer, it use Q345 steel to produce main beam, use Q235 steel to produce bucket body. The yield strength of Q345 steel is greater than that of Q235, and it is more suitable as the material for the main load-bearing girder. Q235 has better plasticity and welding properties and is suitable as the main material for the body. Main beam upper plate to be 14mm thickness, down plate 16mm, middle plate 8mm. With this main bram, the 3 axle U shape rear tipper semi trailer can load 40-50tons without problem. According to clients' requirements, we can customize different axles and loading weight.

Our U shape rear tipper semi trailer can transport bulk cargo, coal, ores and construction materials. There are no dead corners in the corners of the U-shaped box, and the discharge is cleaner; Q high-strength board is used to reduce the tare weight; the damage to the box by the mine head is reduced; the U-shaped structure lowers the center of gravity and avoids overflow of goods.

Specification

Type | |

Loading capacity | 60ton |

Dimensions | 9200x2500x3800mm |

Main Beam | Height:500mm,Upper plate:16mm, Middle plate:10mm, Bottom plate:18mm, Material:Q345B steel |

Thickness | Bottom:12mm, Side:10mm |

Axle | 3axles 13T/16T ,FUWA/ BPW/ ZY Brand |

Lifting system | HYVA hydraulic lifting system, model:FC214-5-09030, lifting |

King pin | JOST brand or Chinese brand 2.0 or 3.5 inch |

Landing gear | JOST brand or Chinese brand 28tons |

Suspension | Mechanical suspension(Germany or America type) or Air suspension(China brand or BPW brand) |

Steel Spring | 90(W)mmx13(Thickness)mmx10 layers |

Tire | 12.00R20 or 315/80R22.5 12 pieces |

Feature

The design is scientific to ensure safety:

the frame and axle loads and hydraulic system of the U shape rear tipper semi trailer use AUTOCAD, PRO/E and other scientific technologies, and are analyzed using relevant software such as finite element analysis. To ensure the safe operation of the dump semi-trailer;

Hydraulic cylinder:

Hydraulic cylinders use well-known brand HYVA hydraulic cylinders, with good performance, good configuration, and easier access to spare parts.

Axle:

Dump semi-trailer adopts professionally manufactured high-quality axles and world-renowned brands. This type of axle has a strong bearing capacity and is not easy to deform;

Suspension:

This 3 axle U shape rear tipper semi-trailer uses a newly designed suspension system and Dutch technology imported from the United States. The axle load is balanced, and the traction road angle is reasonably designed to reduce the instantaneous friction and sliding distance between the tire and the ground.

Advantage

1> High-quality steel can help the rear dump trailer reduce the weight of the body, and with high strength, it can carry more heavy objects, and can load more tons when you load heavy objects.

2> Arrange experienced workers to use superb welding technology to weld the dump semi-trailer to be more firm.

3> U-shaped box and optional accessories such as box thickness can be customized according to your needs and ideas.

Our Advantage

Competitive price - we are the leading semi-trailer manufacturer in China with our own factory. According to a lot of comparisons and feedbacks from customers, our prices are more competitive than others.

Rapid Response - Our team of hard-working individuals is available 24/7 to respond to customer inquiries and questions. Most issues can be resolved within 12 hours.

Fast delivery - because we make it ourselves, we can work overtime to make it. In 80% of cases, we can provide customers with 15-20 days regular trailer delivery.

High Quality-Every process of material selection, welding, sandblasting, painting has a detailed inspection, and is 100% inspected during and after production.

Submitted successfully

We will contact you as soon as possible